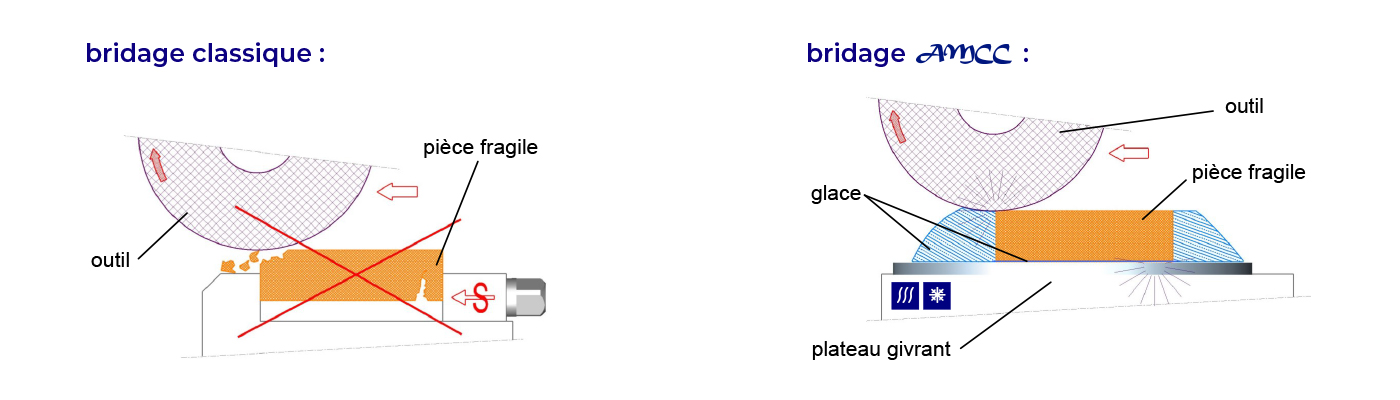

Bridez sans contrainte

En utilisant les propriétés adhésives du givre, AMCC® à développé, pour vos pièces fragiles, un système de bridage :

- sans contrainte

- hyper rigide

- mono face

- rapide et simple d’utilisation

- pour toutes formes

- pour toutes matières

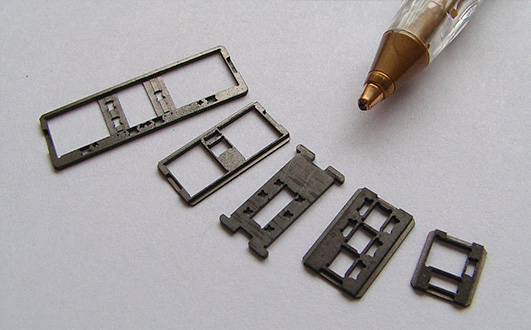

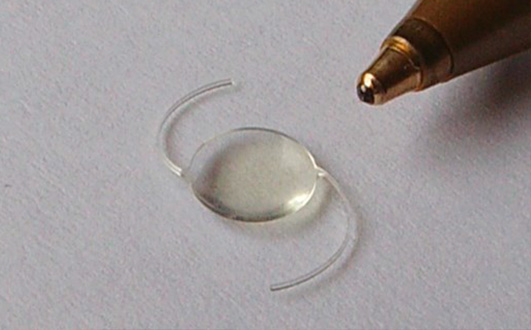

Applications

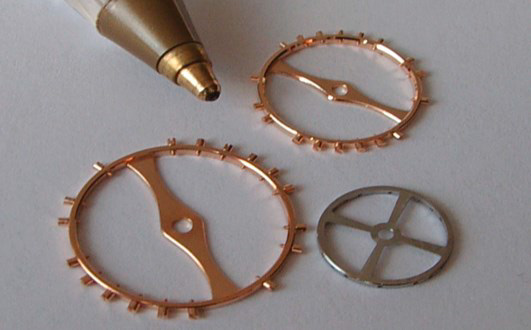

Métaux précieux

Graphite

Plastique

Ferrite

Lunette

Balanciers

Céramiques crues

Matériaux Frittés

Composite

Époxy

…

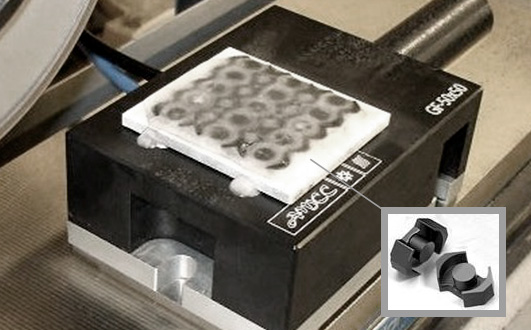

Utilisation

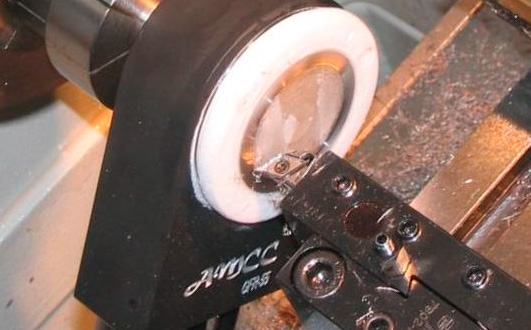

Les plateaux givrants à air comprimé AMCC s’utilisent en fraisage, tournage, rectification, diamantage…

Mise en œuvre est très rapide :

- raccordez l’appareil au réseau d’air comprimé

- pulvérisez de l’eau sur la plaque de congélation

- déposez la pièce à usiner

- actionnez le bouton de régulation de T ° ou le levier gel/dégel

- en quelques secondes l’eau gèle et la pièce est bridée

- le débridage, tout aussi rapide, s’effectue en inversant la manœuvre

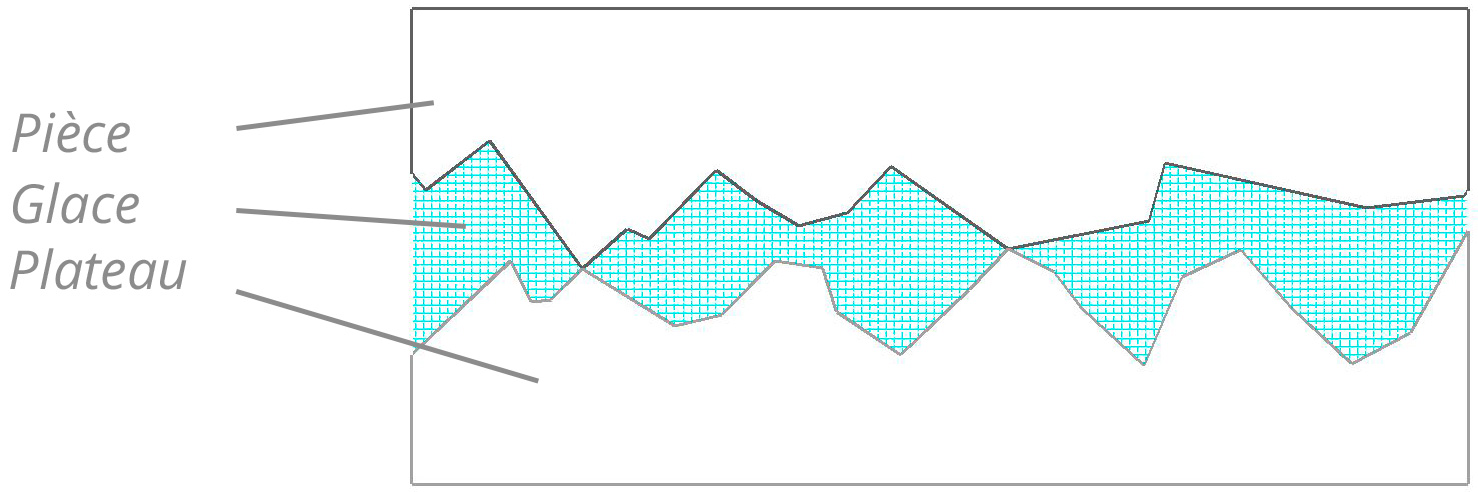

L’épaisseur d’eau sous la pièce étant nulle, la répétabilité en ‘’Z’’ dépend seulement du référentiel.

Coupe (échelle microscopique)

Le plateau évacuant les calories générées par l’usinage, la lubrification classique devient inutile.

(*) Systèmes brevetés

(**) air propre et sec (3.2.2. suivant AFNOR E 51.301)