Intraocular Lens

« Frost » is an extremely strong adhesive used in many micro-mechanicals applications for minuscule parts that are difficult to handle as watch hands for example.

Thanks to this natural property, AMCC Icing Plates uses it as a clamping system that has many advantages:

- Rigid bonding is achieved with several materials as PMMA, acrylics, silicone, etc…

- Stress-free mechanical clamping.

- Deep cooling enhances cutting surface condition’s, more especially for hydropho bic materials.

- No solid residues after deblocking parts.

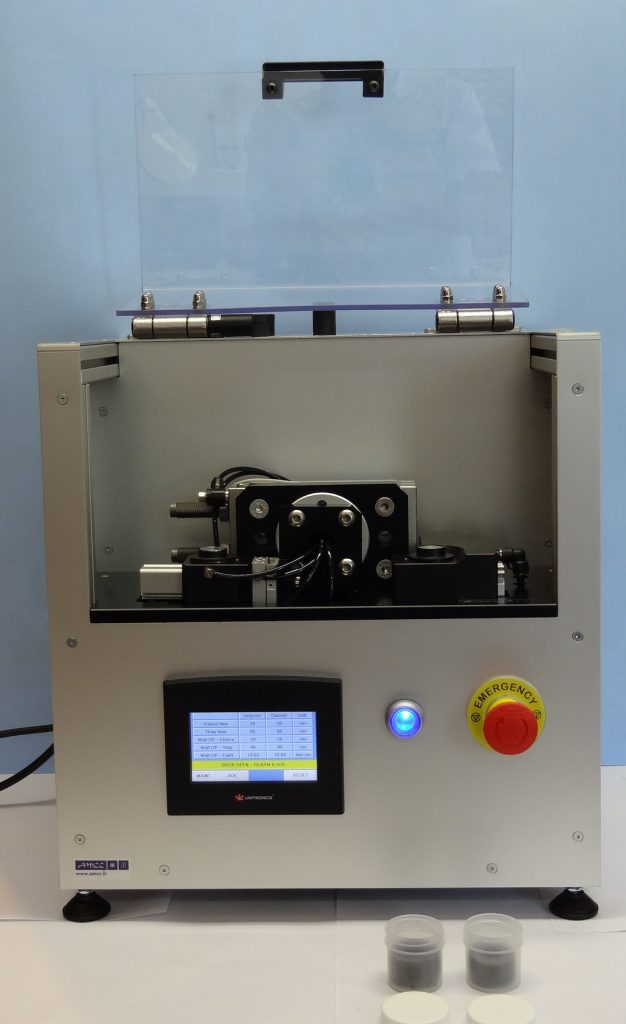

AMCC GF plates are cooled down by a thermal exchanger(¹) with double flux(¹), therefore needing only compressed air(²) to function.

The Icing Plates are user friendly for IOL manufacturing: Spray water on blanks; position blank on the freezing mandrel; in few seconds water will freeze and machining can began. Deblocking is even easier by reversing air flow from freezing to thawing.

Originally made for being used in workshops for air-space industry these Icing Plates have been showed in areas making fine parts, and more especially in the Intraocular lens industry.

As showed above, AMCC icing plates allows high productivity gains while improving IOL manufacturing quality.

We stay at your disposal for any further information, so please do not hesitate to contact us.

(¹) Patented systems

(²) Compressed air clean and dry (7 bars, 3.2.2. as per AFNOR E 51.301)

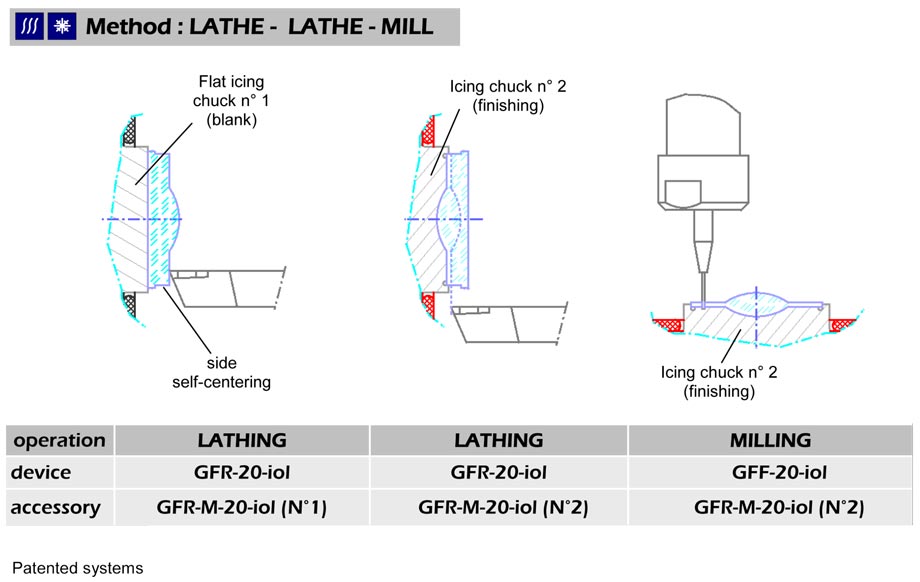

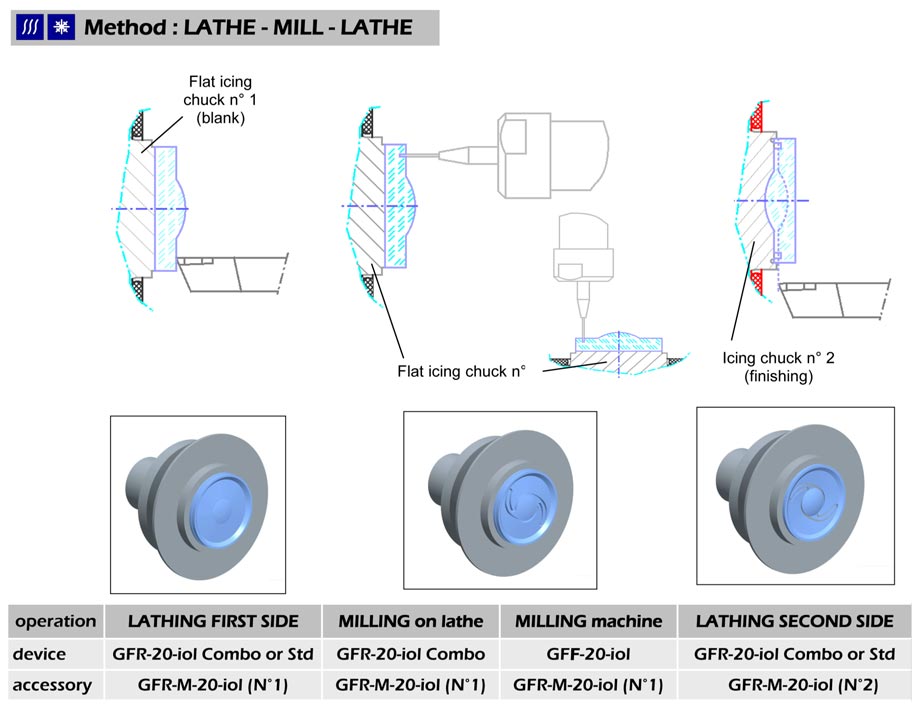

Machining Methods

As showed above, AMCC icing plates allows high productivity gains while improving IOL manufacturing quality.

We stay at your disposal for any further information, so please do not hesitate to contact us.

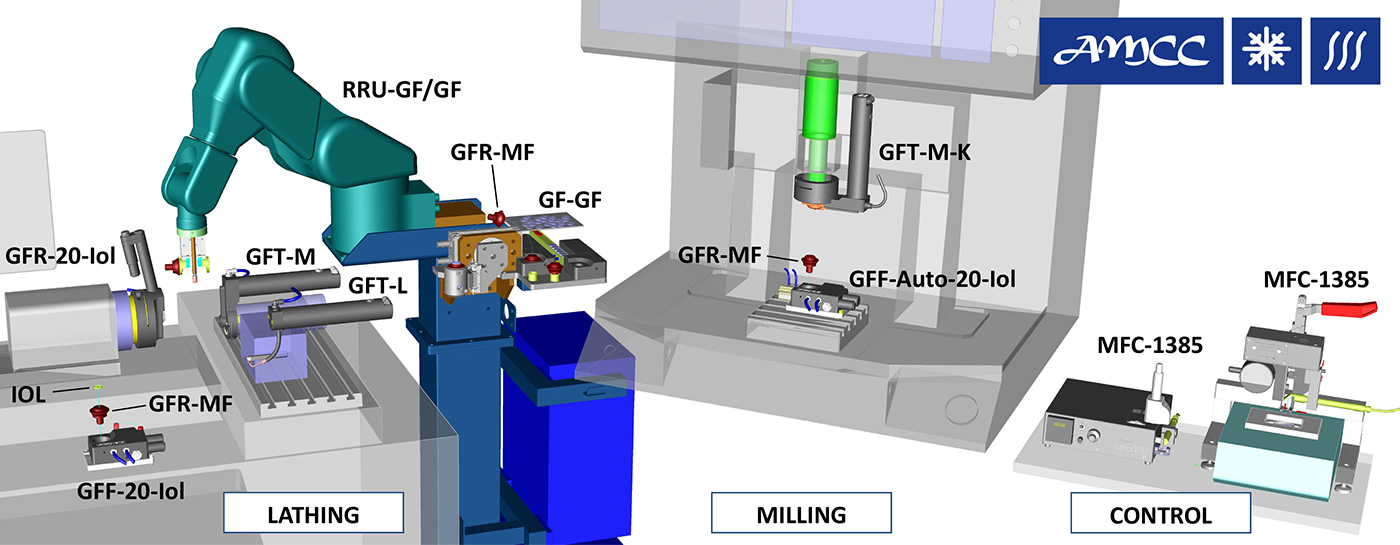

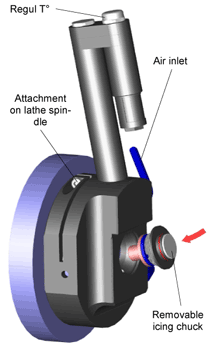

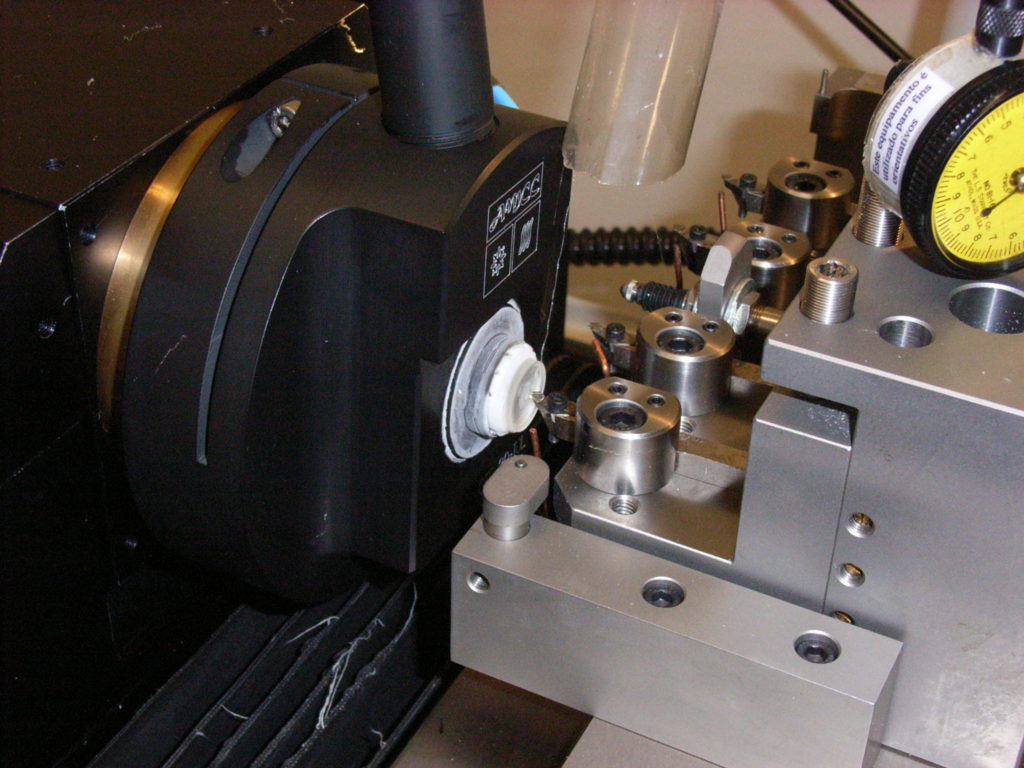

Lathing

Using GFR-20-IOL icing plate for lathing perfect rounded blanks is no longer a necessity as any collet is avoided. Thinner blank can be used, leading to a material saving with a deep core freezing and easy repositioning for the next step.

Freezing mandrels GFR-20-IOL are interchangeable in order to fit various manufacturing steps. Generally the mandrel used for the first side is flat to fit the blank surface, while mandrels for the second side are machined with a mirror image of the lens profile.

Thanks to an optional external centering device, positioning of lathed disks can be achieved easily.

As the original “dead length” collet is used underneath the freezing device, shifting to a “classical” manufacturing stays simple.

(1) Patented systems

(2) Compressed air clean and dry (7 bars, 3.2.2. as per AFNOR E 51.301)

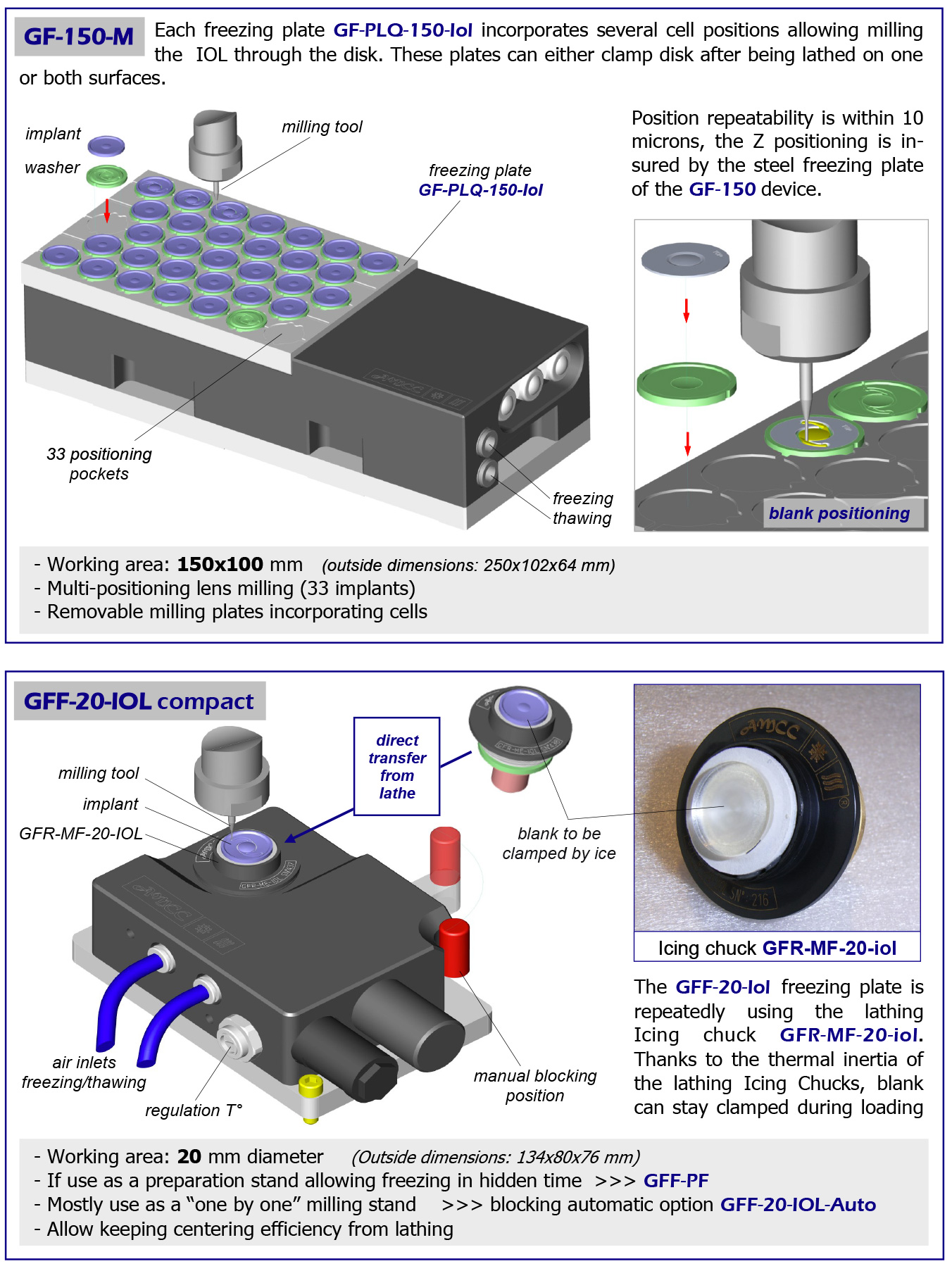

Milling

Following the manufacturing sequence choice, the milling step can be accomplished either on the GF-150-M icing plate or on the GFF-20-Iol freezing stand (one by one).

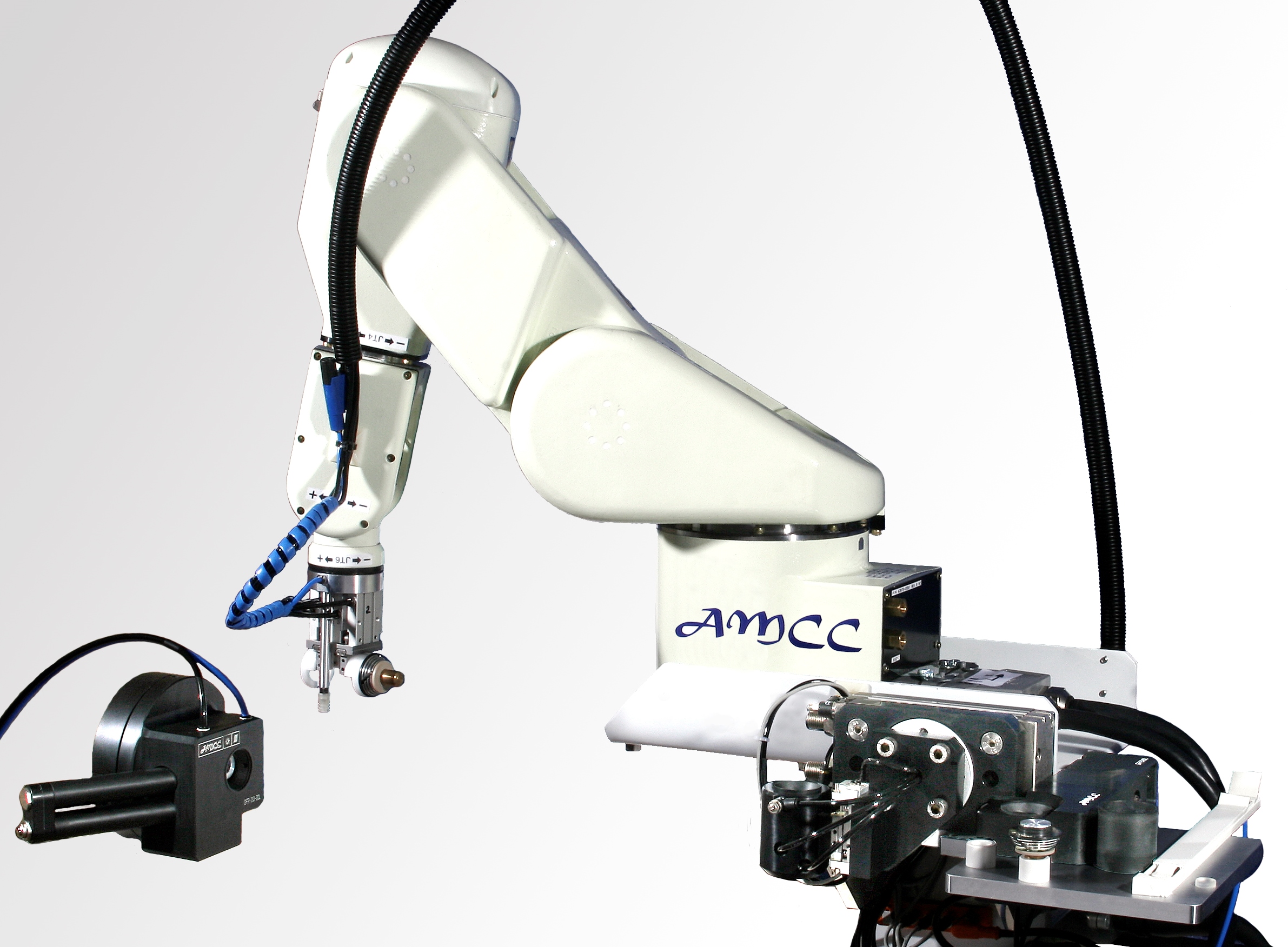

IOL reversal unit

The reliability of the reversal system GF-GF, associated with gripping frosting chucks GFR-MF-20-Iols ensures extremely precise positioning accuracy on both faces.

Semi-automatic GF-GF

The semi automatic unit GF-GF1 is designed to flip of IOls, betwen first face machining to the second side machining. The reliability of the reversal system, associated with icing chucks GFR-MF-20-Iols, ensures extremely precise positioning between both faces.

Demonstration 1 Demonstration 2

> NO DATA SHEET

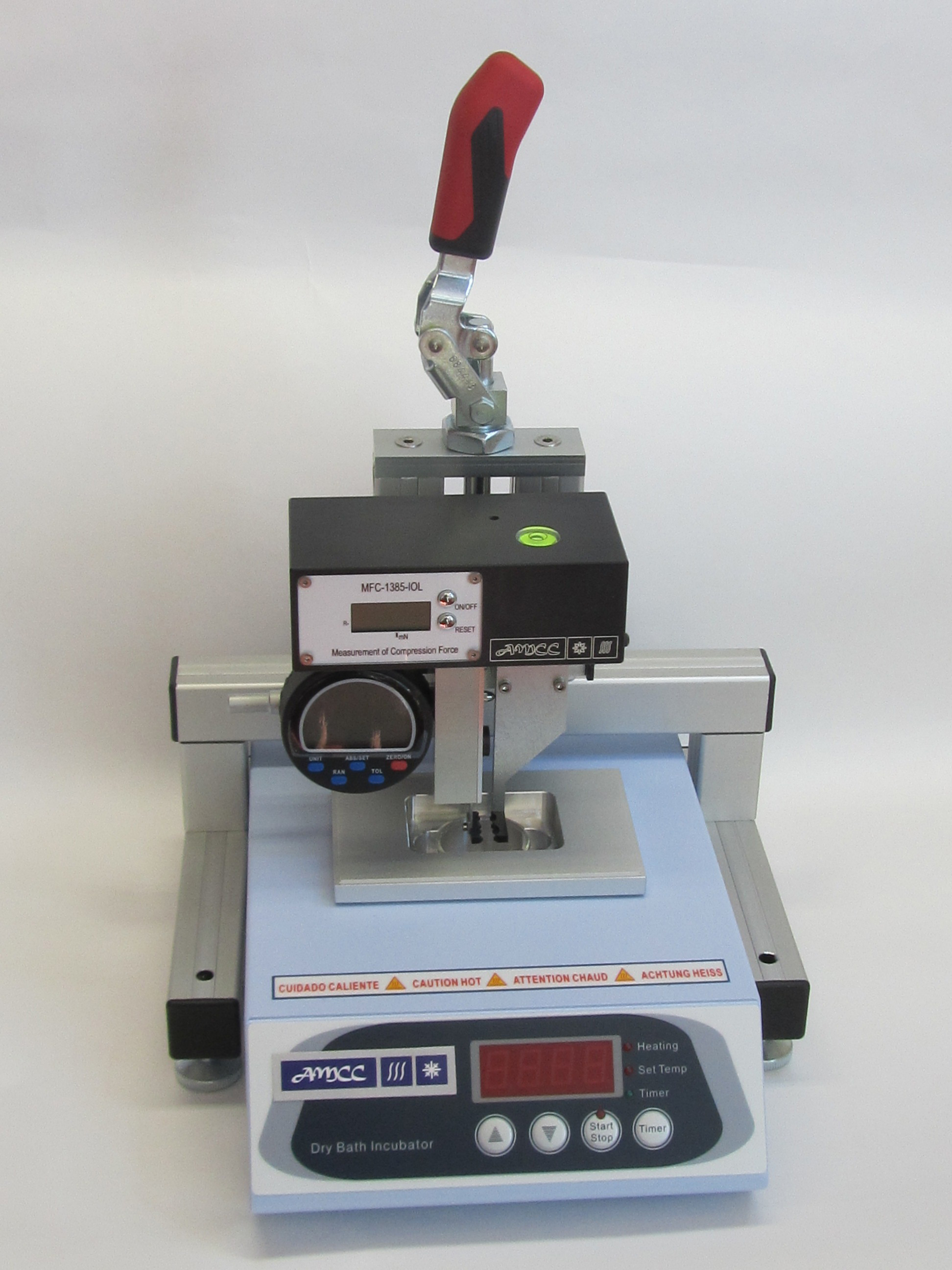

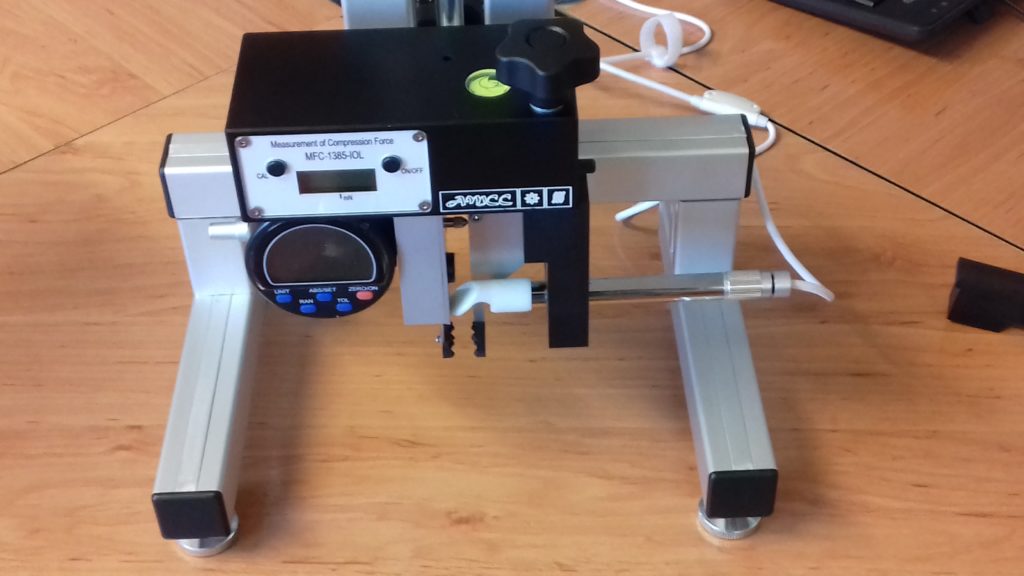

Control

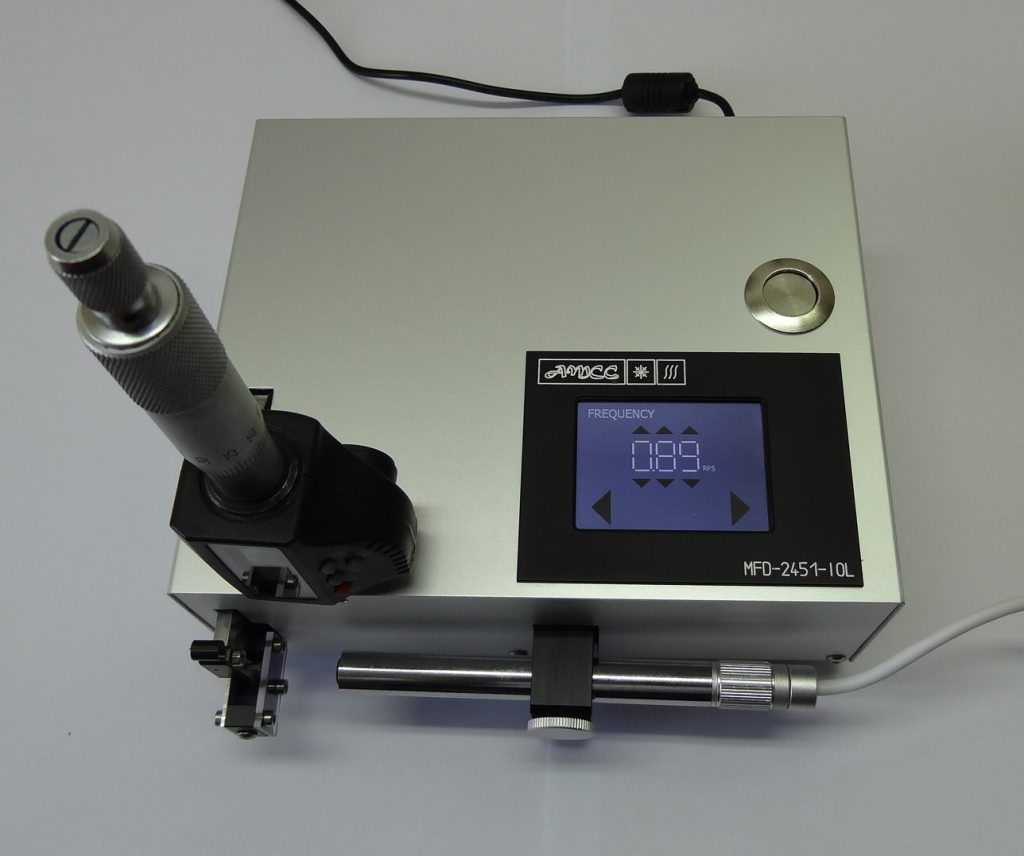

MFD-2451-IOL

Dynamic fatigue durability test following standard ISO 11979-3 appendix G